Customising old cars gets harder as the supply of original vehicles dries up, but there are plenty of Ford chassis in America which are ripe for the picking. Tobias Ballard enjoys giving them a new lease of life as speedsters, and his latest project takes things to another level…

Words and photography: Zack Stiling

If there’s one thing guaranteed to divide opinion in this scene, it’s the question of modifying classic cars. One side will point out, rightly enough, that building hot rods has been a part of American car culture since the days of the Model T, and that allowing creativity to flourish makes the scene more interesting. The other side maintains, also quite rightly, that original cars are scarce and must either be preserved or lose their historic value.

Enjoy more Classic American reading in the monthly magazine.

Click here to subscribe & save.

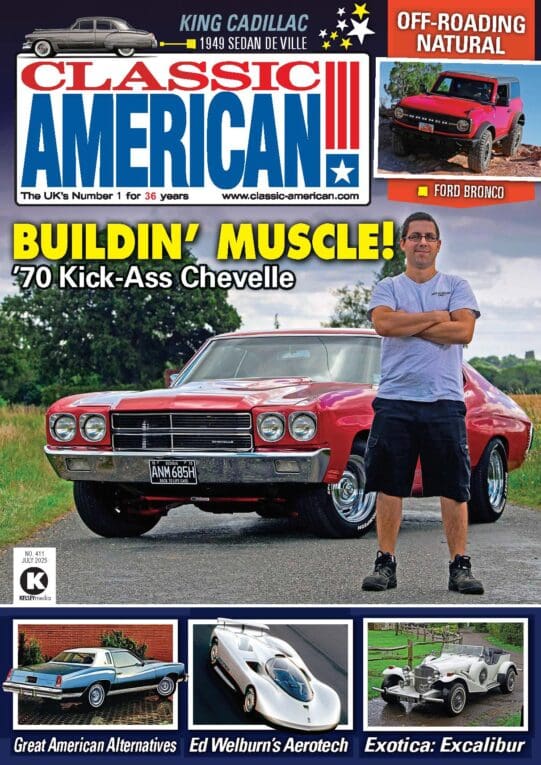

As the supply of original cars gradually diminishes, it’s a problem which is only going to get worse, but there are ways around it for now. If you want to build a unique, period-style hot rod without compromising the originality of a historic car, you have only to import one of the thousands of good, usable Model T or Model A chassis still to be found lying around in American barns and yards, then build everything else around it. Tobias Ballard of the Model A Revival Company has been doing exactly that for 10 years now. The car you see on these pages is not his first Model A special – in fact, it’s about his 20th – but it represents the pinnacle of his work so far.

Why Model As? It was a rather out-of-the-ordinary business deal which got Tobias into them, as he explains: “A guy came to me when I was selling Land Rover parts. I was 23 years old, he turned up at my door, bought some parts, left me a load of cash and asked if I could send them to Argentina. I shipped them, then got a fax from him saying ‘Thanks. I’d also like a London bus and a taxi. Can you send them to Argentina?’ He sent me the cash, but it was quite a lot more than it actually cost to ship them. There was about £12,000 left over and he told me to keep the money. He said: ‘Are you interested in old cars? There’s a guy over here selling Model A Fords. Would you like to spend some of that money?’ I flew to Argentina and bought three…”

Among the three was a 1928 phaeton which Tobias got married in and now serves a dual function as a trials car and, when the mud’s been cleaned off, as a rolling advertisement for the company. “It was that car that got me into Model As once I realised how easy it is to work on them and find parts. I started doing work on other people’s and the rest is history.

“As soon as I realised there was an abundance of rolling chassis available, I had the idea to build a speedster, but it wasn’t until 2008 that I started buying up all the chassis and the parts with which to do it. In 2012, I started building them.” Tobias has now put together 18 or 20 Ballard Specials, mainly for customers, but his newest creation is very much a showstopper and intended solely for his own enjoyment. Whenever somebody attempts something unprecedented or exceedingly difficult, their justification for doing so is very often ‘just to see if I can’, and Tobias was thinking along similar lines.

There have been twin-engined Model Ts before, but the only twin-engined Model A, to the best of our knowledge, was one built by French Ford racer Charles Montier in the early 1930s. However, that ceased to exist long ago, and any plans Montier might have made are also no more. Tobias simply wanted to see if he could do what no man had done for 90 years. As when anyone attempts something so bold and ambitious, he encountered his share of naysayers, and he’s pleased to have proved them wrong. The secret to success, he says, was “a lot of heartache and some broken crankshafts”, but the process can be simplified into two main steps.

The first was to join the two engines together by way of a coupling which must necessarily be extremely strong, and which had to be designed and fabricated from scratch. The second was to get the engines running smoothly together, which was achieved by setting the crankshafts 90 degrees apart from one another, so that they run as if they were one eight-cylinder rather than two fours. Once that had been achieved, Tobias had only one problem to overcome which concerned the complex belt-drive system contrived to drive the water pumps and dynamators of both engines. Slipping belts compromised the function of the pump and dynamator of the rear engine. Tobias’s solution was to modify the pulley of the front engine to incorporate a sprocket driving a chain to the front dynamator which is, in turn, connected to the rear dynamator by a solid shaft.

Cooling the twin engines was always going to be an issue, so they benefit from an electric fan; that and the dynamators being the only non-vintage part on the whole car. Tobias even succeeded in sourcing some original 1920s spark plugs. From the clutch back, everything is standard, although the propshaft and torque tube obviously had to be shortened.

It all sounds very easy when summarised like that. However, in reality it was anything but. Also, there was more to it than just connecting the engines. As with all Ballard Specials, there’s a lot going on internally. Tobias knows how get 80bhp from an engine which originally only produced 24. He increases the compression ratio from 4.2 to one to six to one and increases the bore by 0.145in, resulting in an increase in total capacity from 3.3 to 3½ litres. He finishes them off by converting them to shell bearings and fitting a high-lift cam. There’s also the option of a twin-carb conversion, which Tobias maintains makes an enormous difference to the Model A’s performance, and one day soon he intends to have the Twin-Engined Special running on four carburettors.

While it was obviously a lot of work, it all came together surprisingly quickly. Although the project’s entire duration was about two years, he reckons he was only working on it for about 18 weeks. It was ultimately completed in time to debut at the 2023 New Year’s Day Gathering at Brooklands. Tobias’s staff at the Model A Revival Company comprises himself, a mechanic and an expert panel-worker, for whom the creation of the body presented no difficulty. “The original idea,” says Tobias, “was that we would throw a body together, see how it looked on the chassis, and then take it all apart and completely restore it. In the end, though, we decided to keep it as it is, looking like an original, rusty old speedster from the period.”

As impressive as it is to look at, with open pipes it sounds truly fearsome and quite unlike anything else. According to Tobias, though, it’s docile and beautifully well-behaved. “It drives really well. It’s one of the nicest speedsters we’ve built because of its weight distribution. The sheer power of 7.2 litres is mind-boggling in a car which weighs 750kg, if that. We need to put it on a rolling road to find out just how much power it produces, but it will wheel-spin in top gear.” It handles nicely and stops on command despite the brakes being completely standard. Tobias says: “It uses an original but all-new braking system. If a Model A’s got new cast-iron drums instead of the pressed steel they used to have, and all-new shoes and linings, they’re really efficient.”

Brilliantly, the Twin-Engined Special is registered for the road, and its furthest drive so far has been a 50-mile round trip, but its real purpose is obviously competition. Tobias has just joined the Vintage Sports-Car Club in order to enter his phaeton in trials, and he wants to see if the club will grant eligibility to the Special which he intends to use in hill climbs. Hopefully, then, the Twin-Engined Ballard Special will soon be coming to a hill climb near you. Until then, there’s not much left to do with it except, perhaps, upgrade the back axle. Says Tobias: “You can buy a higher-ratio crown wheel and pinion which will add 10mph to whatever it will do, but we’re still in the early stages. I don’t want to blow it up while there’s still a lot of people interested in seeing it…”