Words: Graham Heeps

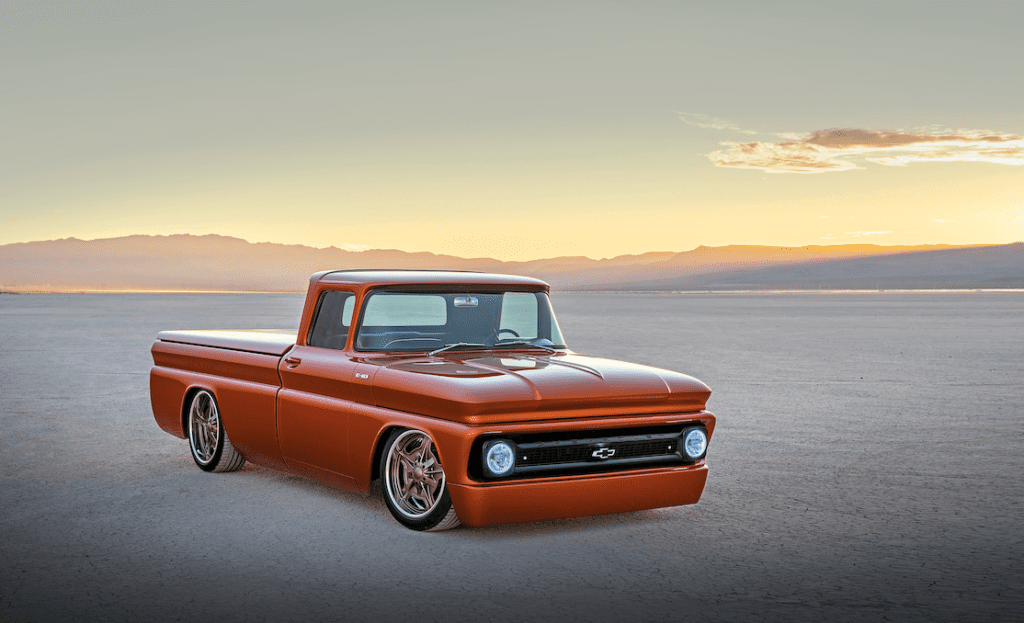

Chevrolet is offering a glimpse of an electric crate-engine future with the E-10 Concept, an incredible 1962 pick-up truck that redefines what a resto-mod could be. We talk exclusively to the team behind this high-voltage hot rod…

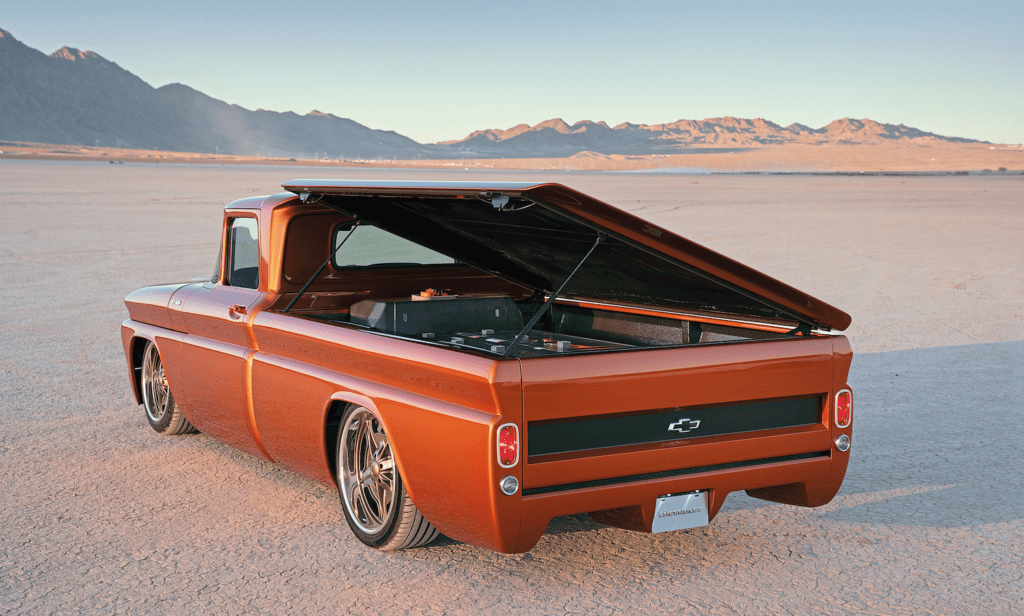

One of the stars of the 2019 SEMA Show in Las Vegas was Chevrolet’s innovative E-10 Concept, which married a 1962 truck with the powertrain from the marque’s Bolt EV. The goal is to show how a possible ‘Connect & Cruise’ eCrate engine could open the door for amateur builders to re-power their classic Chevys with an all-electric set-up. The parts aren’t in the GM Performance catalogue yet, but if the truck’s creators have their way, they will be, soon.

The E-10 is much closer to a production offering than Chevy’s first effort at showcasing a plug-and-play electric powertrain, the eCOPO Camaro Concept from 2018. Where that drag car featured a bespoke battery and motor set-up, most of the E-10’s technology is lifted directly from the Chevrolet Bolt EV – or two Bolt EVs, to be precise.

Enjoy more Classic American reading in the monthly magazine.

Click here to subscribe & save.

That includes the two 950lb 60kWh battery packs that lie flat under a hard tonneau cover in the bed, one atop the other. The associated power electronics and even most of the cables are straight out of the Bolt, too. The set-up means that the two packs can be charged independently, and therefore in less time – a necessity given Chevy’s goal to take the E-10 on the seven-day, seven-city Hot Rod Power Tour in June 2020.

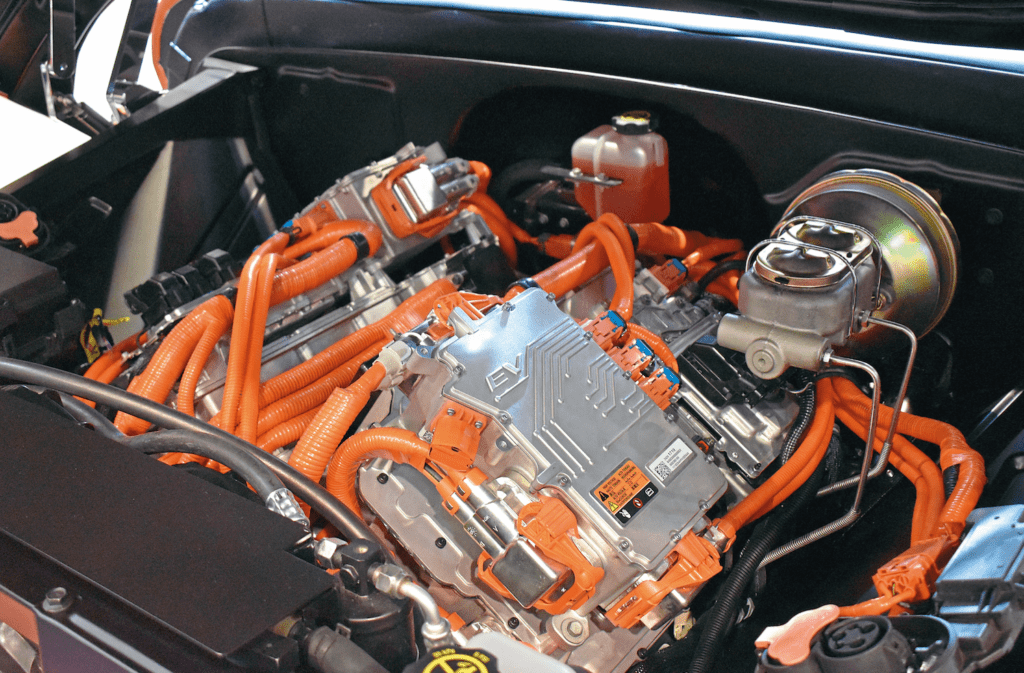

“Each pack has an independent heating and cooling system, straight out of a Bolt, but with custom plumbing,” explains Prashant Ahire, who led the E-10 propulsion team for Chevrolet. “The cells have a very limited range for optimum performance, so we don’t want them to be too cold or too hot. The coolant is cooled by the A/C condensers in the front of the truck; those too are straight from the Bolt. The only major things not from the Bolt are the electric motors.”

Motor setup

The motors sit under the hood below the two inverters, whose mounting angles give the illusion of V-cylinder banks. The angled installation actually came from functional considerations, not form, however.

They were simply too long to fit flat! Chevy has opted to fit two development motors for a total of around 450bhp. The eCOPO’s externally sourced motors were on a single shaft but with these in-house, stackable GM motors, each has its own shaft. A male spline on the back plugs into a female spline on the front so by removing the front cover off the motor, another can be bolted straight on.

Production Bolt motors are rated at about 200bhp (149kW) and don’t go beyond 400v, but the development units in the E-10 are designed to handle up to 800v and with the appropriate wiring, each could produce up to 400bhp – or 1000bhp+ for three in a stack. “The motors have the LS bellhousing bolt pattern, so they bolt directly to a SuperMatic 4L75-E four-speed transmission and drive the rear wheels,” adds Russ O’Blenes, GM’s director of performance variants, parts and motorsports.

“The truck is a blast to drive. We put a bunch of gear in it – there’s a 5.38 rear axle ratio and with the 4L75-E the first gear is over 3:1, so you’ve got a 16-17:1 ratio in first. Add in torque multiplication from the torque converter and it’s pretty crazy, even with the 6000lb weight.”

Chevy claims a 0-60mph time of around five seconds and quarter-mile times in the high-13-second range. Almost 90% of the vehicle electronics are carried over from Bolts. Key to bringing the two parallel battery systems together is the unique body control module, a standalone, CAN-based controller that talks to the two independent Bolt systems – effectively enabling two Bolt cars to be driven by a single pedal.

Some other control modules, such as power steering, were deleted, but the rest of the Bolt’s electronic safety features remain. “If you look at the rawness of eCOPO, which was pure race, this is the next step to get more safety, more production-based stuff to move forward,” says O’Blenes.

In-house restoration

Piecing together the E-10’s powertrain was only part of the job for the Chevy team tasked with getting the truck to SEMA. Bodywork mods included a smoothed head and tailgate, a recessed 1964-66-era grille, shaved drip rails and extended lower rockers. “We cheated and bought two donor trucks,” laughs Rich Downing, GM’s programme manager for speciality show vehicles, who oversaw the E-10 project.

“We had a body undergoing restoration at the same time as we were developing the chassis and powertrain elements. Then we took the chassis from one and the powertrain from the other and mated them together. The leftover pieces will be used for something new.

“Our design studio had the body and did all of the metalwork,” he continues. “We relied on an outside shop just to squirt the tri-coat orange paint; everything else was done in-house, including the interior trim. In a tight, 18-week build programme, there were a lot of late nights.” The E-10 Concept has already been tested at GM’s Milford Proving Ground but further testing of its controls and other elements will be required before June in order to certify it as road legal.

“We have to make sure that all the systems function properly before our safety team can approve taking it on public roads,” says Ahire. “We have to be very careful. But we have time.”